E2 history

What would Adam be without Egon. And Egon without Adam? In 1964 they meet for the first time. How this meeting inspired a product that has kept its appeal to this day is a story unto itself.

Wieland, the Blacksmith

“How would you build a model of the dome of Berlin’s Memorial Church?” Professor Rolf Lederbogen asks this question in 1963 in search for the right person to head the new metal workshop at the Karlsruhe Institute of Technology (KIT). It comes at a time when Adam Wieland, a 27-year-old master blacksmith, is ready for a new challenge. His solution prevails over 50 competitors – and soon he is setting up the new workshop with 12 workplaces. Teaching modules include Materials Science, Manufacturing Technology and Modelmaking. Metalworking becomes part of the core curriculum for some 190 architecture students a year. Fascinated by his ingenious ideas, they give him the moniker “Wieland, the Blacksmith”. After all, the Germanic legend was also a master of his craft.

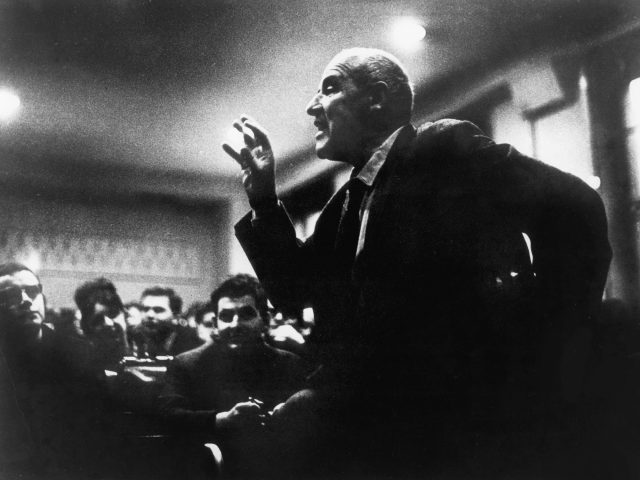

Eiermann and the X

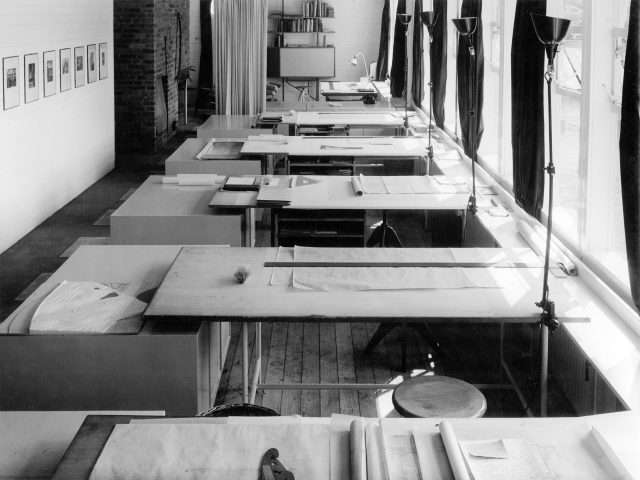

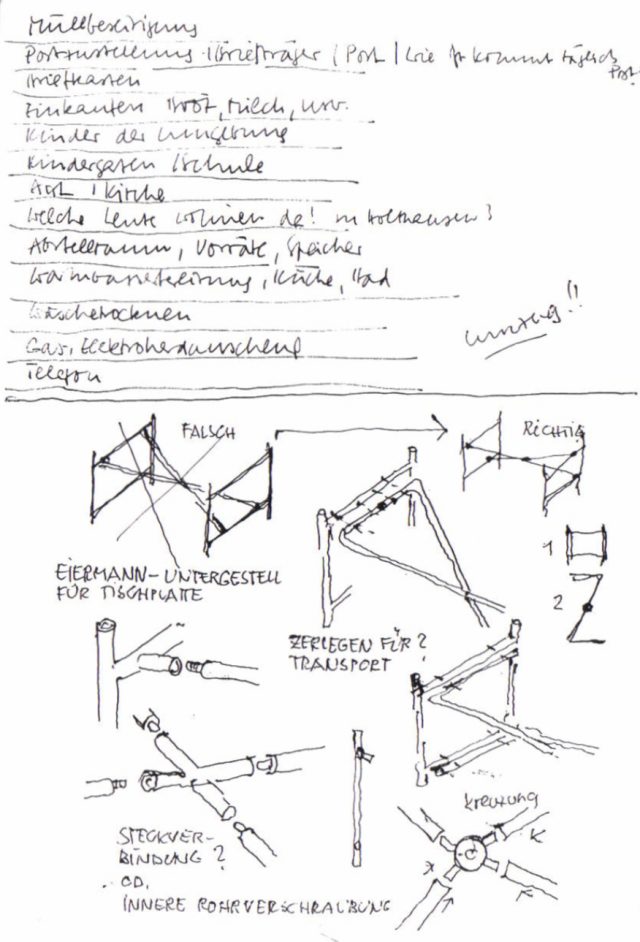

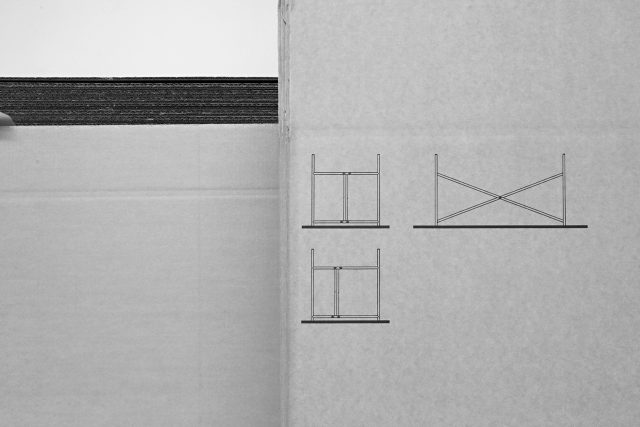

In 1947 Eiermann is appointed Professor of Architecture at the Karlsruhe Institute of Technology. His strictly rational and geometric design idiom defines the “Second Modernity” movement und informs the institute’s profile. He teaches the “Lost Generation”, the first generation after the war. Students throng to hear his lectures, sitting on stairs and window sills, carpooling all the way from Stuttgart. Eiermann relates stories from real life – such as the construction of the “Langer Eugen” (English: “Tall Eugene”) in Bonn, an office tower built for German Bundestag representatives, or the Kaiser Wilhelm Memorial Church in Berlin. Considering architecture as a synthesis of the arts, he designs it with the furniture included. His first steel tube frame dates back to 1944, created for his office in Beelitz-Heilstätten, the “barracks”. In 1953 Egon Eiermann designs a sturdy, functional desk for his offices at the Karlsruhe Institute of Technology. Pared down to the essentials, it is the first of its kind to feature the characteristic, space diagonal cross-bracing. The crossbars sit at an angle, all elements are welded together. A simple wooden desktop placed loosely on the frame serves as a drawing board. The “Eiermann table” is born – and goes into small volume production as a desk-cum-drawing board. Its first buyer is the Karlsruhe Institute of Technology, using it for the fitout of its training rooms.

A moveable solution

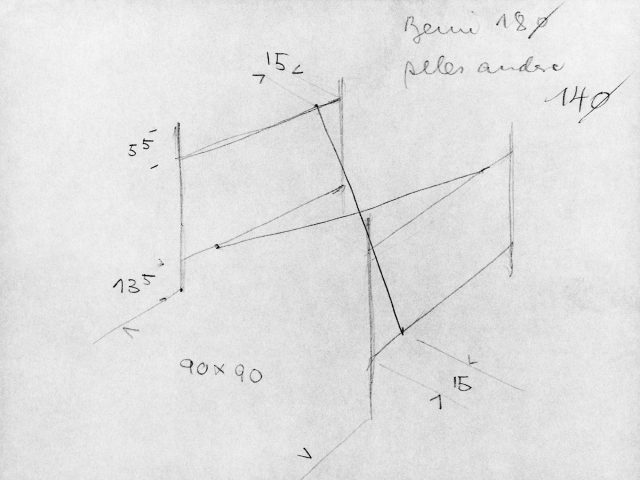

The “Eiermann” is soon indispensable at the KIT. Its untreated steel frame is painted and sprayed by students – and not infrequently nicked. Long rows of tables in the hallways serve to present the students’ final projects. In 1964, Adam Wieland and Egon Eiermann meet for the first time in the context of these student projects. Eiermann respects the ambitious expert and his dedication to his students. Wieland assists the “guru” with metal constructions and prototypes. When Eiermann assistant Klaus Brunner decides to move to Freiburg in 1965, he has a special request: He dreams of a transportable version of the Eiermann table that fits in his Citroen. He asks Wieland to cut up the welded frame so it can later be reassembled with plug connections. But Wieland has a better idea: He cuts the frame into four components and designs them so they can be screwed together. Using vertical crossbars, he increases the frame’s stability and functionality. An optimised tubular cross-section reduces the weight. The Eiermann table becomes suitable for everyday use – and Egon pats Adam on the back.

A table becomes an icon

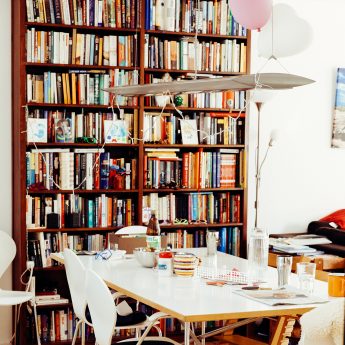

The screw-mountable “Wieland table” goes into production in the same year. Finished in black, it sells for 28 deutschmarks. When his students see the freshly painted models standing in the metal workshop, the easy-to-dismantle drawing board rises to meteoric fame. As interest in the welded frame begins to wane, Wieland soon sells ten units per week – and counting. In order to meet the rising demand, productions at night are relocated to his parents’ garage. On 20 sqm Wieland now employs two after-hours welders. The products are stored in the basement and sold from his residence and at the KIT. The conference rooms in the latter are now also equipped with the iconic table. The range is supplemented with accessories and other designs: height adjustments replace the bricks used by students. The standing desk, the children’s desk and a version with crossbars offset to the back are added. The table is now more flexible than ever – and more popular still. Not only architects, but also other creative professions are beginning to discover its marvels.

Room to grow

In 1993 Professor Rolf Lederbogen goes into retirement. Wieland also leaves the KIT and becomes his own boss at the new “Adam Wieland Metallwerkstatt” metal workshop. The “Metallwerkstatt” addition to his name serves as a reminder of his time as workshop supervisor. His new address is Alte Kreisstraße 12. On 100 sqm, he now employs three welders who work by the piece. His clientele has long exceeded the more than 5,000 students he taught over 60 semesters. Many of them have gone on to set up their own offices, fitting their first premises with his table frame. Popular among architects, professors, urban planners and designers, the “Eiermann” spreads from Karlsruhe throughout Europe, the USA, the Middle East and Australia. Wieland now supplies big names such as David Chipperfield Architects, Henn or Herzog & de Meuron. These are joined by several universities, including RWTH Aachen, ETH Zurich and Bauhaus University in Weimar. At the turn of the millennium, Adam Wieland looks back on a success story of almost 40 years and several hundreds of thousands of sold tables. His life’s work – ready for the next generation.

Peter, will you take over?